Wiskind group has a 41-year history and is involved in the mental facade, mental roof, cold room system, steel building system, modular building system, and cleanroom system.Wiskind clean tech focuses on the cleanroom area for more than 11 years and it has become the biggest manufacturer of the cleanroom panels, doors, and windows in China.

Also, we are the market-leader supplier for the pharmaceutical industry and hospital in domestic.

For the overseas market, we have exported our products to usa, russia, iraq, uae, israel, thailand, myanmar, vietnam, egypt, etc.

We are committed to the most influential enterprise in the cleanroom enclosure.If you have a project now, you are so welcomed to send an inquiry.We promise you the best quality at the best price.

Basic Information

| Cleanroom Panel & Wall Panel & Ceiling Panel | ||

| *The following are standard configurations,Highlighted in bold can be customized* | ||

| Stock Size | Width*Thickness | 980mm(W)*50mm(T),980mm(W)*75mm(T),980mm(W)*100mm(T) |

| 1180mm(W)*50mm(T),1180mm(W)*75mm(T),1180mm(W)*100mm(T) | ||

| Max Length | Machine made:6.5m | |

| Hande made:7.0m-7.5m | ||

| Type | Machine made | |

| Hand made | ||

| Surface | Material | Color Steel Sheet |

| Stainless Steel Sheet | ||

| HPL | ||

| Coating | PE,PVDF,SMP,HDP | |

| Color | Color RAL 9002-WhiteGray | |

| Fill-in | Core material | EPS(PS,Polystyrene) |

| Rockwool | ||

| Paper honeycomb | ||

| Aluminium honeycomb | ||

| PU(Polyurethanes) | ||

| PIR( Polyisocyanurate) | ||

| Matched | MGO(Magnesium oxide board) | |

| Gypsum | ||

| Frame | Machine made | 0.5mm(T) Galvanized steel sheet |

| Two sides block on length direction | ||

| Hande made | 0.6mm(T) Galvanized steel sheet | |

| Four sides block | ||

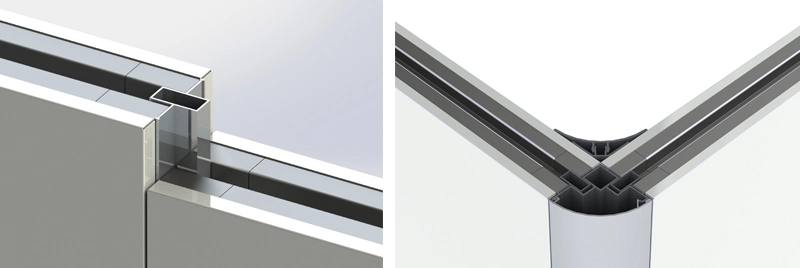

Cleanroom Panel Structure

Easy to install and remove. Not easy to accumulate dust, and easy to clean.

Introduced the world's advanced automatic production equipment such as PUMA, RAS and ACL in Italy, and independently developed the world's first automatic made-hand cleanroom panel production line, which is 6-8 times more efficient than the traditional cleanroom panel production line. Including roll forming, automatic cotton, automatic glue spraying, double-track shaping and temperature control system, robot palletizing. The system has a high degree of automation, the processing efficiency and product quality is stable, the largest production capacity reaches 2 million Square meters/year, and can produce a variety of core material cleanroom panels, cleanroom panel continuous production system as a key development project in Shandong province in 2016 and in 2018 the successful acceptance of the expert group members agree that this system has reached the international advanced level.

1. Are you a Factory/Manufacturer Or Trading Company?

We are a manufacturer with 40 years' experience of production and have a modern standard plant of 1,000,000 m².

2.How about your lead time?

It will take 3-7 days for budget and design according to the drawings after receiving the deposit. 15-30 days if there are some special sizes.

3. Can you sell products all over the world?

Yes, we have 4 subsidiaries, 13 offices, and more than 100 technical supervisors all over the world, providing timely and face-to-face service for customers.

4.How about your core competitiveness?

We have the first automatic production line in the world. Compared with the traditional manual production line, the production efficiency increased by 6-8 times, leading to most competitors. That means lower cost and higher quality.

5. Do you have your own construction team?

No, but all of our cleanroom panels and connected parts are easy for disassemble and installation due to our excellent design. What's more, we provided the instruction and videos for installation and we can send our professional supervisor to the site.

6. How many kinds of products do you have?

At present, we have more than 30 different products, including a cleanroom wall panel system, ceiling system, clean room door, clean room window and so on.

7. Can you provide samples? Is it free or extra?

Yes, we can provide samples for free, but we would appreciate it if freight to collect.

8. What are your terms of payment?

30% T/T prepaid, 70% T/T before delivery. We can discuss payment if we have more cooperation in the future.